The field of coffee processing is constantly evolving. Recently, innovative coffee producers have been experimenting with anaerobic processing, in which coffee is fermented without oxygen. This different process, results in rare and exotic flavours.

Although anaerobic fermentation is relatively new, aerobic fermentation, in which oxygen is included in the process, is common practice. This is common practice for traditionally processed coffees. Fermentation begins immediately after the coffee is harvested due to the presence of water, sugar, bacteria and yeast. The sugars and acids in the coffee pulp are then converted into various acids, CO2, ethyl alcohol and other compounds. Coffee always ferments slightly differently depending on whether it is a washed, natural or semi-washed process, resulting in different flavour variations.

Anaerobic fermentation

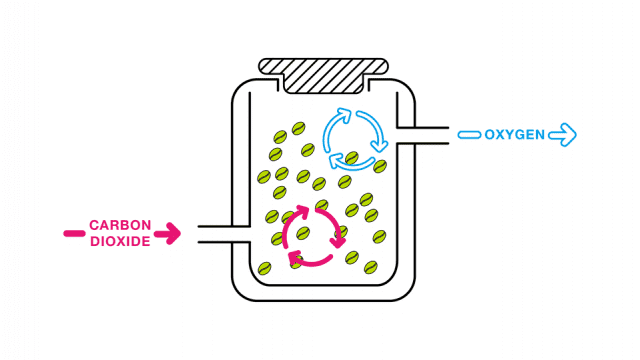

It is a method of fermenting coffee in a closed tank with a one-way valve that serves to stop the oxygen supply to the vessel. The temperature of the tank is also regulated for a better result. Unlike the types of fermentation used in traditional coffee processing, it is therefore a controlled and purposefully prolonged fermentation. This process can be carried out in specialised tanks, barrels or even in plastic Grain-pro bags. The important thing is that the coffee is sealed for a certain period of time without access to air. This can be done before the cherries are stripped of their pulp or afterwards. In both cases, the micro-organisms start to break down the glucose molecules, a chemical reaction that generates CO2 and heat. This leads to the oxygen being pushed out of the tank, through the one-way valve. The bacteria naturally found in the coffee cherry produce enzymes during this process that cause the formation of less complex compounds such as organic acids and alcohols.

How does anaerobic fermentation affect the final taste of coffee?

Managing and prolonging the fermentation of coffee leads to a change in its chemical composition and therefore its organoleptic profile. Fermentation can enhance the taste or create different flavour profiles of the same coffee. For example, coffee with a 48-hour fermentation process will not taste the same as coffee with a 100-hour fermentation. Dr. Britta Folmer says in The Craft and Science of Coffee that “removing the pulp through underwater fermentation reportedly increases acidity and aroma and reduces astringency.”

On the other hand, too long fermentation can have the opposite effect, losing acidity, body and aroma. Coffee producers strive to find a balance in which flavour and aroma are enhanced without losing the coffee’s key characteristics.

Carbonic maceration

The only difference between anaerobic and carbonic fermentation is that in carbonic maceration, after the coffee cherries are placed in the fermentation tank and the tank is closed, carbon dioxide is injected into the tank. This displaces all the oxygen. As in anaerobic fermentation, it is important to control temperature, pH and sugar levels.

How does carbonic maceration affect coffee and why is it used?

The reason for using carbonic maceration instead of anaerobic fermentation is that injecting carbon dioxide into the tank and removing all the oxygen slows down the fermentation process.Because there is no oxygen present (i.e. no oxidation), the breakdown of glucose is slower, as is the development of pH. It also makes it easier to control different parameters to obtain different results. Sasa Sestic, a world champion barista and pioneer in the application of this process, claims that by controlling the temperature you can regulate both the acidity and the sweetness. At low temperatures, acidity increases, while at high temperatures, sweetness increases.

As with anaerobic fermentation, the aim is to improve the coffee’s characteristics by increasing aroma, improving sweetness and acidity, and obtaining a coffee with a richer flavour structure.

Lactic fermentation

Anaerobic coffee fermentation and carbonic maceration are two of the most common processes currently used to enhance the organoleptic properties of coffee, but they are not the only ones.

There are other processes to achieve these results, some in more experimental stages than others. We are talking about lactic fermentation, fermentation with kombucha mushrooms, wine yeasts or water kefir. Coffee contains various bacteria that carry out the fermentation process, including lactic acid bacteria. These are the same ones that are responsible for the fermentation processes in dairy products, but also in fermented vegetables.

In the lactic fermentation process of coffee, conditions are controlled by oxygen regulation, for example through the multiplication of these bacteria and others (e.g. aerobic bacteria). This alters the fermentation process so that different results can be obtained.

Some producers are also experimenting with other processes and trying to introduce the bacteria responsible for fermentation in kombucha and kefir mushrooms into the coffee fermentation process. One way to do this is to let the coffee cherries ferment in a kombucha or water kefir solution.

Coffee freezing – freeze-drying

Another of the experimental ways of processing coffee is freezing. Freeze-drying is a process commonly used in food processing. Its aim is to remove water from the food and extend its shelf life. The process consists of various steps. First, the temperature of the coffee is lowered, usually to about -40 °C, which causes the water present in the coffee to freeze. Later, the pressure in the freezer is reduced and the frozen water is sublimated. Eventually, the water is removed from the coffee. Usually, the temperature of the coffee in the freezer is increased and the pressure is reduced to reach the target residual moisture content.

The reason for these experiments with coffee processing is to increase knowledge of its flavours, acidity, sweetness, body in the cup and to increase the potential of the product that farmers sell. We at Goriffee are always excited to try new experiments, as it often happens that they bring out new and interesting flavours or combinations of flavours.